Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

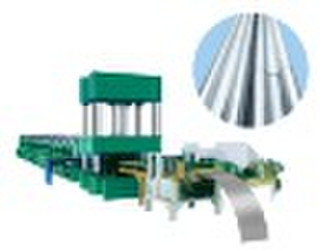

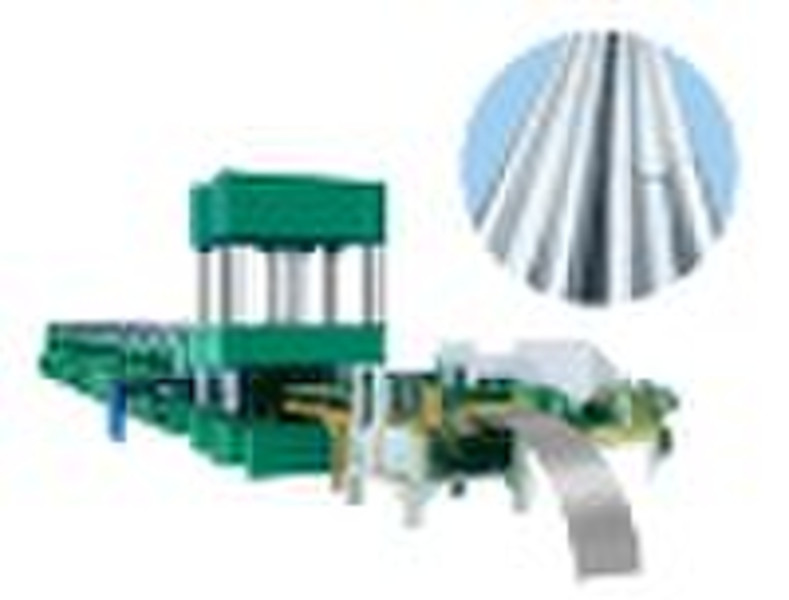

2-wave Guard Rail forming machine

original price: 119 855 USD

Wuxi, China

Production capacity:

150 Unit / Year

Meng Xu

Contact person

Basic Information

I. Craft Flow Uncoiler—— Leveler ——Punching Machine ——Fast Feeding ——Photoelectric Cut-to-length Device —— Main Forming Machine——Straightening Device——Material Collecting Rack ——Control System—— Forming Dies II. Main Technical Parameter 1. Uncoiler It adopts a 6 ton of hydraulic single-arm and internal-inflation type of uncoiler with hydraulic inflation. The inside diameter of the coil is φ500-φ610mm, the outer diameter is φ1500mm, and the effective material hanging width is 500mm. The motor power of hydraulic station is 3KW. It is contolled by a manual valve with self-lock function. The feeding motor power is 2.2KW with a cycloidal pin gear reducer. It is also equipped with a clutch and a pneumatic hold down device.. 2. Leveler It adopts a wallboard type of 4-roller leveler. 2 rollers are for cramping feeding and 5 rollers for leveling. The diameter of leveling roller is 110mm and the material is 40Cr with quenching rigidity of HRC48º 52º. The guiding rolls are equipped both at front and back of the leveler. The inlet is equipped with a hold down roll. The motor power is 7.5KW with a 6-pole normal motor. It adopts a ZQ500 reducer with a speed ratio of 20.49. It is equipped with a φ200 brake. 3. Punching Machine It adopts a YL32-314 four-column type of hydraulic punching machine. The motor power of the hrdraulic station is 22KW. There is one pair of 2-wave guardrail cutting dies, and the specific requirement will be designed and processed according to the buyer’s drawing. The material of die blade and punching head is Cr12MoV. The guiding rolls will be equiped both in front and back of the punching machine. The material of the vertical roll is Cr12MoV and with a rifidity of HRC58º 62º. There will be equipped with one set of standby blade and one set of punching head separately . 4. Fast Feeding There are 2 pairs of fast feeding machines for electric feeding. The power of the motor is 2.2KW. The speed ratio of ZQ250 reducer is 31.5. Hold down with manual regulation. 5. Photoelectric Cut-to-length There are 2 pairs of photoelectric switches for photoelectric cut-to-length. The fixed length is 4320mm and its precision will be less than ±3.0mm. 6. Main Forming Machine The forming machine is designed with 12 steps. An open type of independent rack structure is adopted with an expansion width of 550mm. The rack material is HT200 through temper treatment. There are 3 steps for guiding vertical rolls. The roll shaft diameter is φ80 and the material is 40Cr with thermal refining. The model of the bearing type: fixed side 7216, adjustable side 32216, 4 pieces for each step. There’s 1 piece of up and down transmission gear box of double-output shaft and 10 pieces of underdrive gear box of single-output shaft. The bevel gear module is m=9. The material of the gear box is HT200. The main motor power is 45KW with frequency conversion. It is equipped with a ZQ500 reducer with a speed ratio of 48.57and it is assembled according to No. 5 pattern. The drive gear boxes are connected between each other by one inch of duplex chain transmission and connected with the roll shaft by the universal transmission shaft. The type of the universal transmission shaft is 140-275 which is connected with the reducer by a 1.5 inch of duplex chains transmisson. 7. Material Collecting Rack It adopts a rolling wheel type of rack which is 5 meters long and welded with 6# channel steel. 8.Control System A PLC programme control system is adopted in the production line. The main machine adopts a transducer to adjust its speed and a opposite-type of photoelectronic length measuring system to measure the length and control cutting and punching. The rotating speed, length and qantity can be shown on the touch screen. Every motion of the machine line can be contolled harmoniously manually and automatically.The main electric components are Mitsubishi products and low voltage components are Schneider products. 9. Forming Dies There is one set of roll forming dies for 31085 two-wave guardrail plate. Specific proposal in details shall be made according to the drawings provided by the buyer. The material of the dies are GCr15. The whole quenching rigidity is HRC58º 62º. 10. OthersThe total power of the equipment is 91.9KW, The max. rolling height is 85mm, the max. rolling thickness is 4.0mm and the max. rolling speed is 12 m/min. The material for welding the machine base must meet the requirements. Meanwhile, the welding should meet the requirement of the National Steel Structure Welding Standard.. After rust-cleaning treatment, the equipment must be coated with special paint for antirusting first, the the equipment must be covered with antirusting paint completely, and then it must be coated with high quality of finish paint. The transmitting part should be coated with caution color for distinction.

Delivery terms and packaging

Packaging Detail: fit for sea shipping Delivery Detail: 40-75days

Port: Shanghai Port

Payment term

Telegraphic transfer

-

Payment Methods

We accept: